The pace of digital transformation continues to escalate as enterprises around the world invest in technologies to transform their business processes, products and work practices. Indeed, IDC expects digital transformation spending to reach $1.2 trillion in 2019, an increase of 18% on 2018 figures. In the fifth in our Digital Transformation Challenge series of blog posts, we look at how CKH Innovation Opportunities Development is enabling transformative projects at multinational companies around the world.

All multinationals are on a digital transformation journey. But that's where the commonality ends. Some companies are further down the transformation line, while others are just getting started. There are enterprises with a narrow focus, looking at transforming internal processes in order to remain competitive, and others who are looking at wholesale transformation, ranging from customer experience to operations and workforce enablement.

Digital transformation from the top down

Changing the "if it ain't broke, why fix it" mind-set can be one of the biggest stumbling blocks of any digital transformation project.

Naturally certain sectors are more open to digital transformation. New tech firms, who are digital to the core, tend to see digital transformation projects as business as usual. Conversely, multinational companies in more traditional areas such as manufacturing may struggle to see where digital can play a role. In these two examples the cultural attitudes differ widely, but it's that cultural leadership that's so important in the success of any digital transformation project. But changing that "if it ain't broke, why fix it" mind-set can be one of the biggest stumbling blocks of any digital transformation project.

Where CKH Innovation Opportunities Development excels is engaging with the leadership teams at multinationals. We know from experience that any large-scale change will happen more quickly and efficiently if support filters from the top down. We work with C-level executives to help them understand the areas they're looking to address. Do they want to increase operational agility, improve Service Level Agreements to the end customer, enhance the customer experience, better enable their workforce, or a combination of these goals?

Importantly, we also get the leadership team to think about what success looks like. Having a clear set of KPIs acts as a guide path for any digital transformation project, ensuring that a project doesn't wander off track or take a wrong turn.

Digital transformation doesn't stand still

Often, the nature of embracing technologies and becoming more aware of how digital can revolutionise business processes means that digital transformation projects can grow legs and expand beyond their initial remit. We've worked with a number of large ports in the UK rolling out private LTE networks: the initial goal was to enhance voice and data connectivity, but we're now seeing that this is just the tip of the iceberg of what's possible.

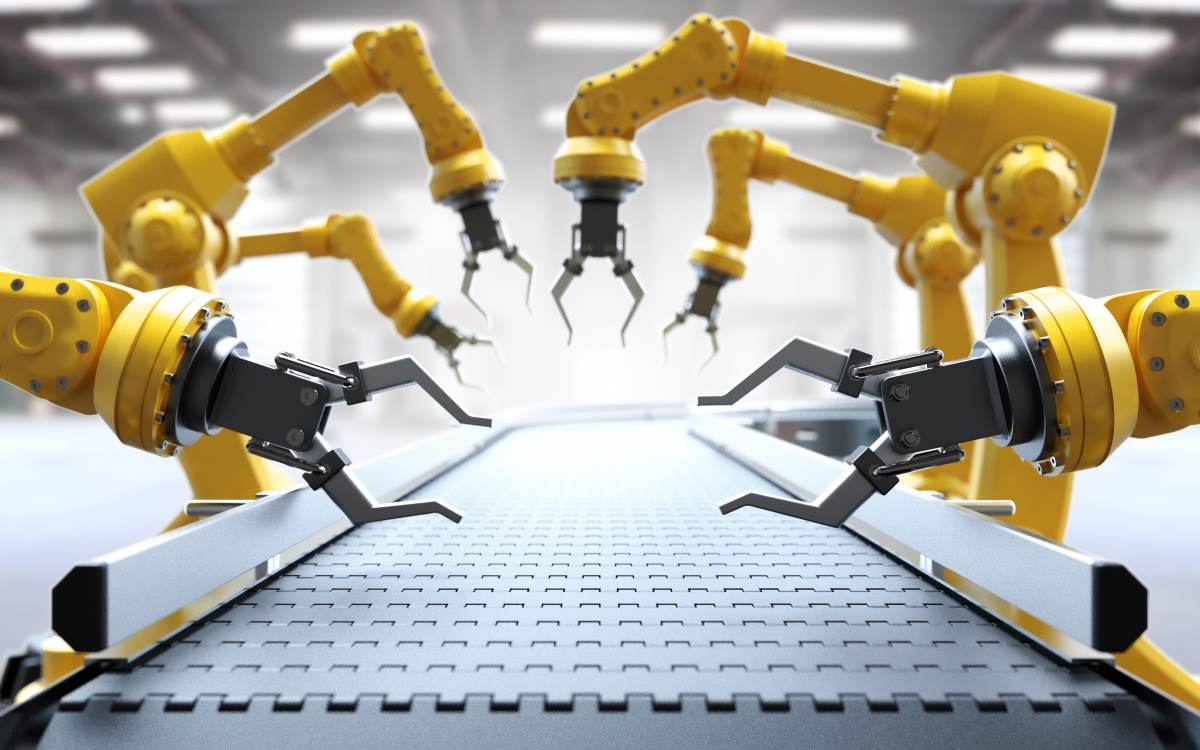

Working with multinational manufacturing firms we're seeing first-hand how they are successfully automating business processes and dramatically increasing efficiencies. Despite a relatively slow start in planning digital transformation projects, the manufacturing sector is having somewhat of a renaissance. IDC says discrete manufacturing and process manufacturing will invest the most in digital transformation projects in 2019 at $221.6 billion and $124.5 billion respectively. Most of this money will be ploughed into smart manufacturing, which comes as no surprise really given the rising interest in the Industrial Internet of Things

Connected machines means that parts servicing is proactive rather than reactive with machines communicating with other machines to alert them of any issues. The beauty of this scenario is companies can start to build a digital picture for each piece of machinery and then start to look at trends through Artificial Intelligence and machine learning. The goal is to get to a point where machines can analyse the data to predict what will break down and where – smart manufacturing indeed.

We’ve spoken already about the power of data and how it can open up doors, create new revenue streams and highlight issues no-one knew existed. Alongside one of our Three Group Europe operating companies, we recently worked with a multinational agricultural firm where data uncovered a problem that may never have been noticed. In identifying this issue the company was able to make significant cost savings and transform one of its key business processes. This engagement was also noteworthy as it showcased CKH Innovation Opportunities Development's partner ecosystem; one of our software partners was instrumental in locating the key piece of the puzzle in this instance.

At CKH Innovation Opportunities Development we never stop learning. Working with multinationals across the globe means we are constantly exposed to the potential of digital. Where we stand out is by applying those experiences across verticals and countries. Our 5 different business verticals within CK Hutchison Holdings means we are experiencing many of the same day-to-day challenges as our customers. We've walked that walk and we can pass on the lessons we've learned to our customers, which means they can hit the ground running on their digital transformation projects.